Answered step by step

Verified Expert Solution

Question

1 Approved Answer

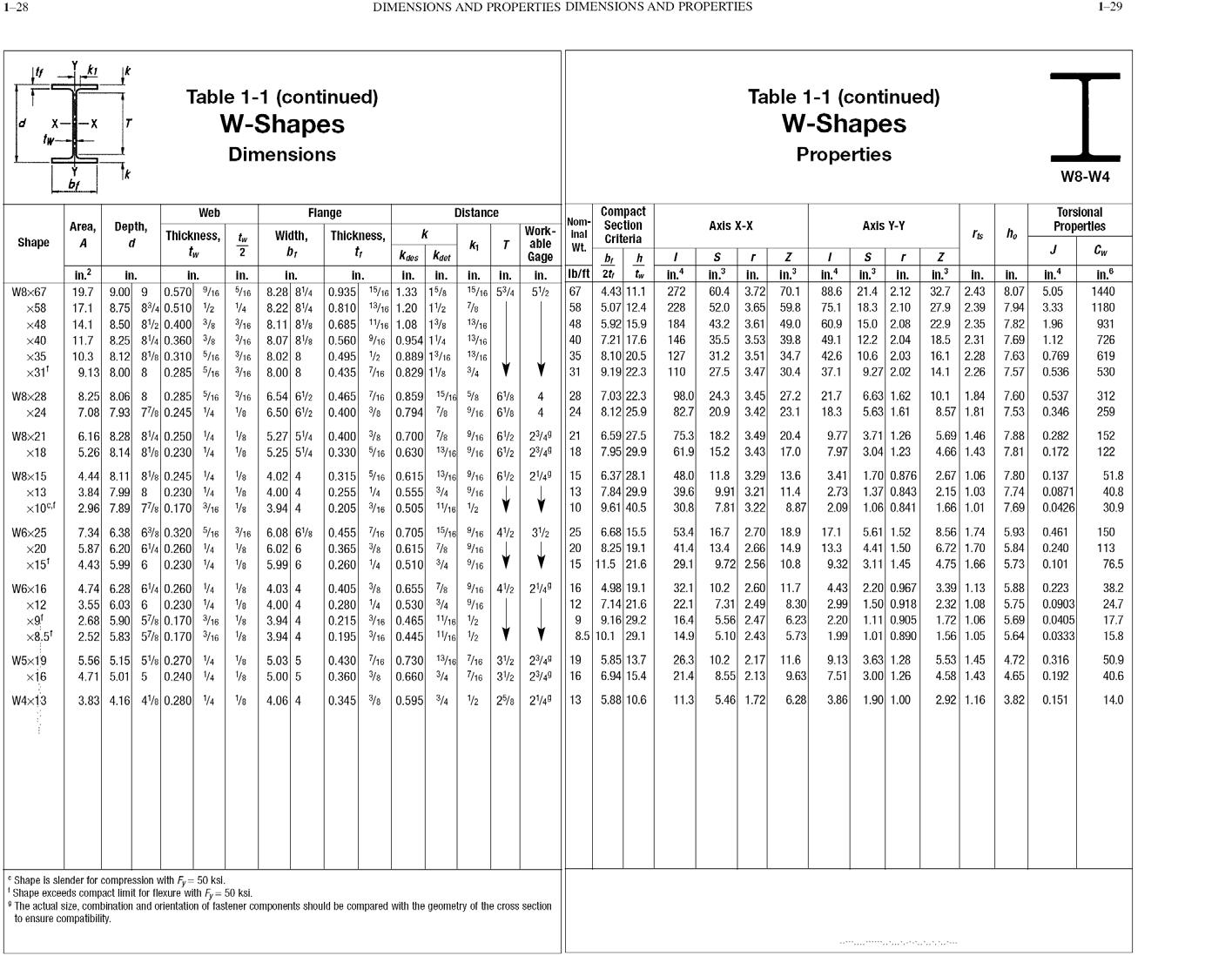

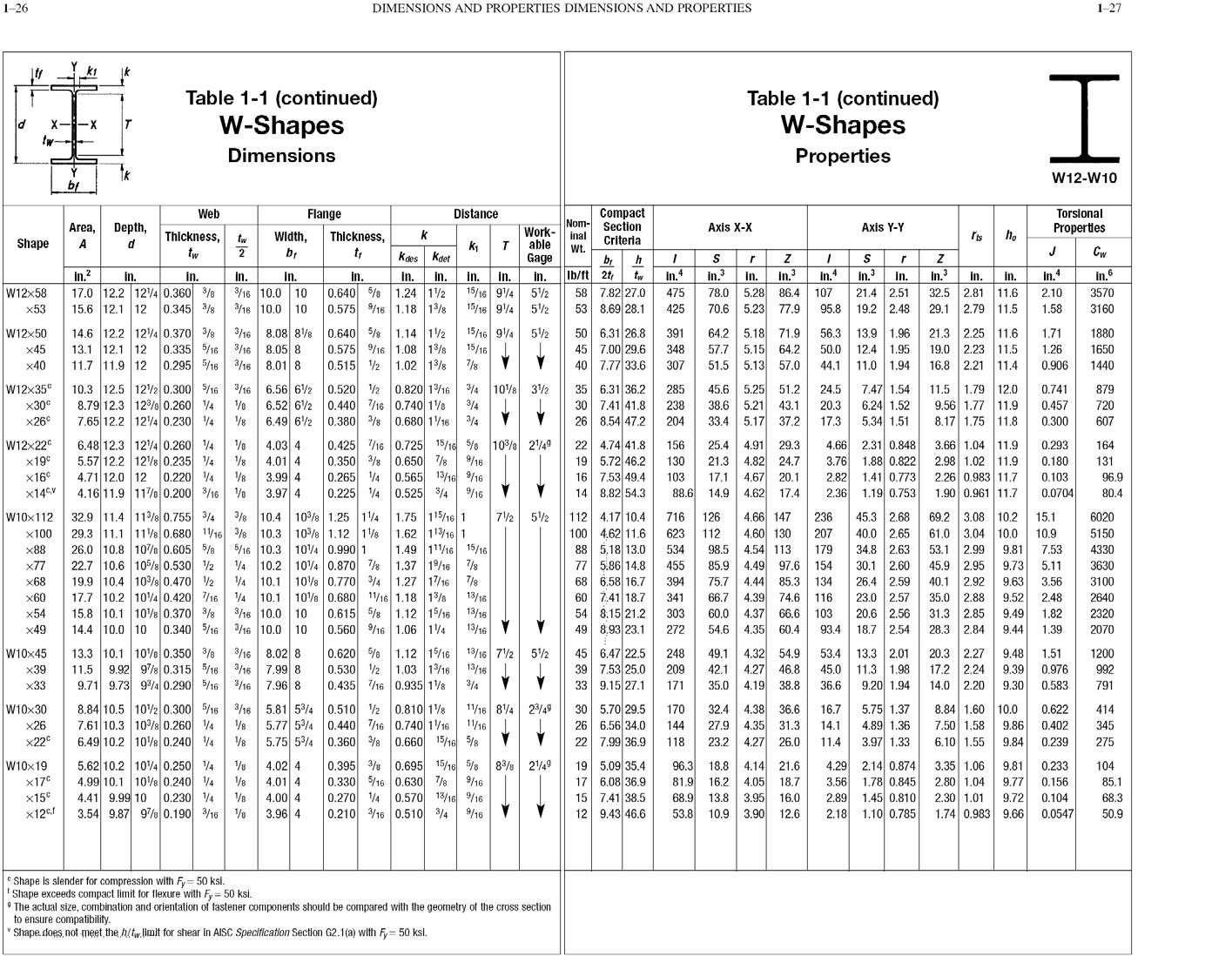

Design a building column made of A36 steel (fy=36 ksi) having length of 10ft using AISC table to support a dead load of 50 kips

Design a building column made of A36 steel (fy=36 ksi) having length of 10ft using AISC table to support a dead load of 50 kips & live load of 80 kips. Assume K=0.9 & E=29,000 ksi. Use LRFD approach for design. Initially assume fcr =0.75 fy. Note: Use “W” section for column member.

1-28 DIMENSIONS AND PROPERTIES DIMENSIONS AND PROPERTIES 1-29 Table 1-1 (continued) W-Shapes I. Table 1-1 (continued) W-Shapes X tw Dimensions Properties W8-W4 bf Compact Nom- Section Torslonal Propertles Web Flange Distance Area, Depth, Work- Inal Axis X-X Axis Y-Y h, k Thickness, tw 2 Width, Thickness, Its Criteria Wt. br Shape A d ki kdes Kaot able Gage tw Cw h in? in. Ib/ft 2t in. in 3.72 52.0 3.65 59.8 43,2 3.61 in. in. in. in. in. in. in. in. in. tw in. in. in. in. In. in. in. in. in. in. 0.570 /16 4.43 11.1 8.28 84 0.935 15/16 1.33 15/8 15/16 53/4 7/8 8.22 84 0.810 13/16 1.20 1/2 13/16 3/16 8.11 88 0.685 1/16 1.08 1/8 13/16 3/16 8.07 8% 0.560 16 0.954 1V4 21.4 2.12 18.3 2.10 9.00 9 8.75 84 0.510 2 8.50 82 0.400 3/8 8.25 84 0.360 3/8 8.12 8%e 0.31o 5/16 3/16 8.02 8 9.13 8.00 8 W8x67 5/16 5/2 67 58 19.7 272 60.4 70.1 88.6 32.7 2.43 8.07 5.05 1440 5.07 12.4 5.92 15.9 40 x58 17.1 14 228 75.1 27.9 2.39 7.94 3.33 1180 15.0 2.08 12.2 2.04 10.6 2.03 9.27 2.02 22.9 2.35 18.5 2.31 16.1 2.28 x48 14.1 48 184 49.0 60,9 7.82 1.96 931 7.21 17.6 8.10 20.5 9.19 22.3 x40 11.7 146 35.5 3.53 39.8 49.1 7.69 1.12 726 0.495 2 0.889 13/16 31.2 3.51 34.7 27.5 3.47 x35 10.3 13/16 35 127 42.6 7.63 0.769 619 x31' 0.285 5/16 3/16 8.00 8 0.435 7/16 0.829 1/8 3/4 31 110 30.4 37.1 14.1 2.26 7.57 0.536 530 8.25 8.06 8 7.08 7.93 77/e 0.245 4 28 7.03 22.3 98.0 24.3 3.45 27.2 82.7 20.9 3.42 23.1 10.1 1.84 8.57 1.81 0.285 5/16 16 6.54 6V2 0.465 /16 0.859 15/16 % 6.63 1.62 5.63 1.61 W8x28 6/8 21.7 7.60 0.537 312 x24 6.50 62 0.400 %8 0.794 7/8 9/16 68 4 24 8.12 25.9 18.3 7,53 0,346 259 0.400 8 0.7o0 7/8 5.25 54 0.330 5/16 0.630 13/16 %16 62 2/49 5.27 54 9/16 62 2%49 6.16 8.28 84 0.250 4 5.26 8.14 88 0.230 4 6.59 27.5 7.95 29.9 3.71 1.26 3.04 1.23 5.69 1.46 4.66 1.43 W8x21 75.3 18.2 3.49 20.4 9.77 7.88 0.282 152 x18 18 61.9 15.2 3.43 17.0 7.97 7.81 0.172 122 0.315 5/16 0.615 13/16 9/16 62 249 0.255 4 0.555 4 %16 0.205 16 0.505 1/16 2 6.37 28.1 7.84 29.9 10 1.70 0.876 1.37 0.843 1.06 0.841 4.44 8.11 88 0.245 4 4.02 4 4.00 4 3.94 4 48.0 39.6 30.8 3.29 13.6 9.91 3.21 11.4 7.81 3.22 2.67 1.06 2.15 1.03 1.66 1.01 W8x15 1/8 15 11.8 3.41 7.80 0.137 51.8 0.230 4 2.96 7.89 7/8 0.170 3/16 V8 x13 3.84 7.99 8 13 2.73 7.74 0.0871 40.8 x10cf 9.61 40.5 8.87 2.09 7.69 0.0426 30.9 7.34 6.38 6% 0.320 5/16 3/16 6.08 6%8 5.87 6.20 64 0.260 4 4.43 5.99 6 0.230 4 16.7 2.70 18.9 13.4 2.66 14.9 9.72 2.56 10.8 0.455 16 0.705 15/16 /16 42 25 6.68 15.5 20 8.25 19.1 11.5 21.6 53.4 41.4 5.61 1.52 4.41 1.50 3.11 1.45 8,56 1.74 6.72 1.70 4.75 1.66 0.461 0.240 W6x25 32 17.1 5.93 150 0.365 8 0.615 /8 6.02 6 5.99 6 x20 1/8 9/16 13.3 5.84 113 x15' 0.260 4 0.510 34 9/16 15 29.1 9.32 5.73 0.101 76.5 9/16 42 249 4.74 6.28 64 0.260 4 3.55 6.03 6 0.230 4 2.68 5.90 57/80.170 3/16 V8 2.52 5.83 57/80.170 /16 V8 4.03 4 4.00 4 3.94 4 3.94 4 10.2 2.60 11.7 7.31 2.49 5,56 2.47 5.10 2.43 2.20 0,967 1.50 0.918 1.11 0,905 1.01 0.890 3.39 1.13 2.32 1.08 1.72 1.06 1.56 1.05 0.405 %8 0.655 7/8 9/16 4.98 19.1 7.14 21.6 9.16 29.2 8,5 10.1 29.1 W6x16 16 32.1 4.43 5.88 0.223 38.2 0.0903 0.280 4 0.530 4 0.215 /16 0.465 1/16 2 0.195 16 0.445 1/16 2 x12 12 22.1 8.30 2.99 5.75 24.7 16.4 6.23 2.20 5.69 0.0405 17.7 x8.5 14.9 5.73 1.99 5.64 0.0333 15.8 0.430 16 0.730 13/16 7/16 32 2/49 0.360 8 0.660 34 5.85 13.7 6.94 15.4 26.3 10.2 2.17 11.6 21.4 3.63 1.28 3.00 1.26 5.53 1.45 4.58 1.43 5.56 5.15 5% 0.270 4 5.03 5 5.00 5 W5x19 1/8 19 9.13 4.72 0.316 50.9 x16 4.71 5.01 5 0.240 4 7/16 32 2/49 16 8.55 2.13 9.63 7.51 4.65 0.192 40.6 W4x13 3.83 4.16 4%e0.280 V4 4.06 4 0.345 % 0.595 34 2 2% 249 13 5.88 10.6 11.3 5.46 1.72 6.28 3.86 1.90 1.00 2.92 1.16 3.82 0.151 14.0 Shape is slender for compression with Fy= 50 ksl. 'Shape exceeds compact limit for flexure with Fy= 50 ksi. The actual size, combination and orientation of fastener components should be compared with the geometry of the cross section to ensure compatibility. **** .

Step by Step Solution

★★★★★

3.36 Rating (149 Votes )

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started