Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Question 1 During a stage one audit, you were selected as a lead auditor together with your audit team to conduct a Quality Management

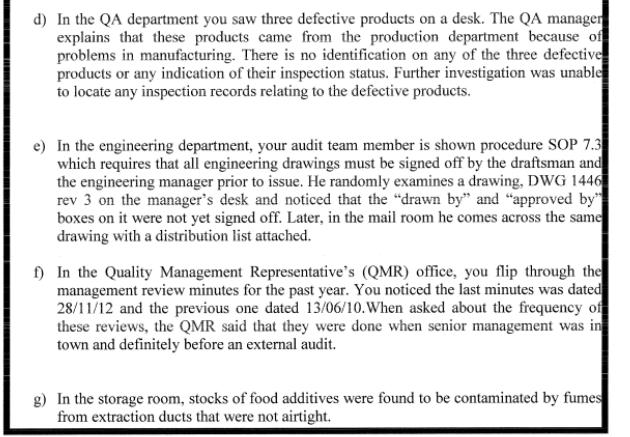

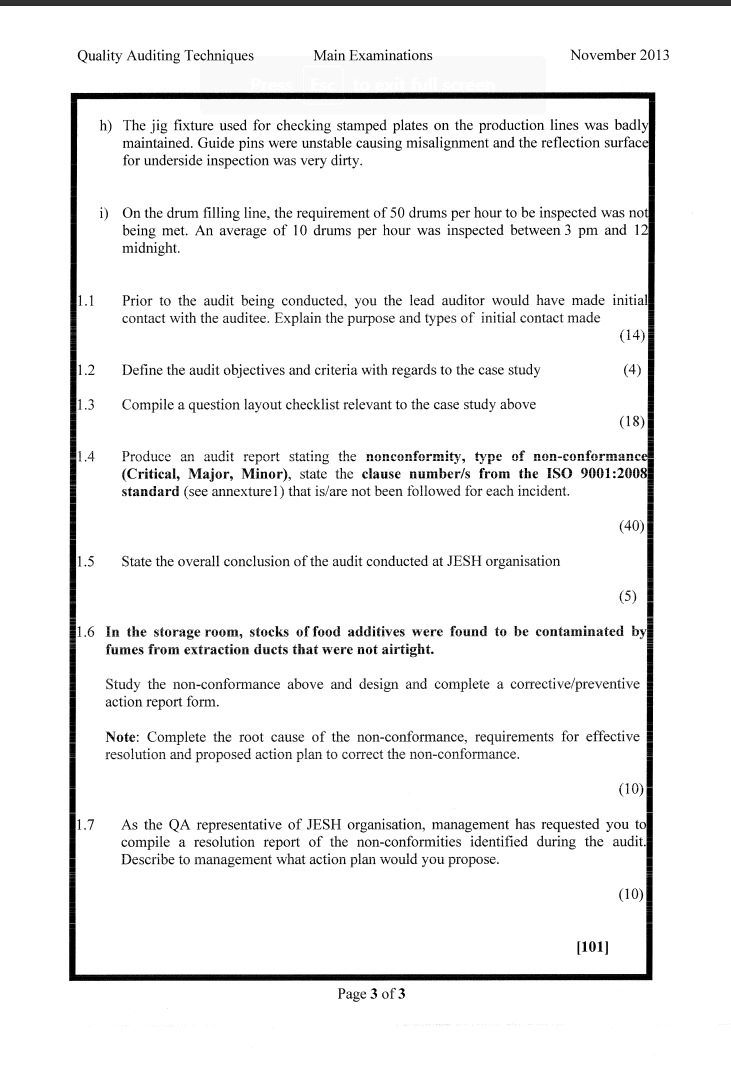

Question 1 During a stage one audit, you were selected as a lead auditor together with your audit team to conduct a Quality Management System (ISO 9001:2008) audit on JESH manufacturing organization. The following activities took place during the audit: a) During a Quality Management System (QMS) document review, you noted the organisation procedure QAP 05, revision 3 states that when testing raw material RH 2005 for acceptance, the results will become unreliable if the test samples are taken closer than 20 inches apart on the material. In the receiving inspection lab you notice an inspector carrying out an acceptance test on material RH 2005. You ask the inspector how the sample position on the material is selected. The inspector replies that they are taken 6 inches apart to avoid wasting material. Upon inquiring about the procedure, you were shown the inspector's copy of QAP 05, revision 2 on a shelf near the inspector's desk. b) In the maintenance department, work instruction TDWI 05 issue 3 which is clearly displayed at all work stations, five of the ten people in the department were not wearing the issued safety glasses when operating machinery equipment. c) In the quality manager's office, one of your audit team members asks to see the schedule for internal audits. This schedule shows that each of the eight QMS processes is audited every six months. The auditor asks the quality manager how the prioritization of audits was decided. The manager says the system was set up three years ago and the organisation has kept to this original schedule. d) In the QA department you saw three defective products on a desk. The QA manager explains that these products came from the production department because of problems in manufacturing. There is no identification on any of the three defective products or any indication of their inspection status. Further investigation was unable to locate any inspection records relating to the defective products. e) In the engineering department, your audit team member is shown procedure SOP 7.3 which requires that all engineering drawings must be signed off by the draftsman and the engineering manager prior to issue. He randomly examines a drawing, DWG 1446 rev 3 on the manager's desk and noticed that the "drawn by" and "approved by" boxes on it were not yet signed off. Later, in the mail room he comes across the same drawing with a distribution list attached. f) In the Quality Management Representative's (QMR) office, you flip through the management review minutes for the past year. You noticed the last minutes was dated 28/11/12 and the previous one dated 13/06/10. When asked about the frequency of these reviews, the QMR said that they were done when senior management was in town and definitely before an external audit. g) In the storage room, stocks of food additives were found to be contaminated by fumes from extraction ducts that were not airtight. Quality Auditing Techniques 1.1 1.2 1.3 1.4 1.5 Main Examinations 1.7 h) The jig fixture used for checking stamped plates on the production lines was badly maintained. Guide pins were unstable causing misalignment and the reflection surface for underside inspection was very dirty. i) On the drum filling line, the requirement of 50 drums per hour to be inspected was not being met. An average of 10 drums per hour was inspected between 3 pm and 12 midnight. November 2013 Prior to the audit being conducted, you the lead auditor would have made initial contact with the auditee. Explain the purpose and types of initial contact made (14) (4) Define the audit objectives and criteria with regards to the case study Compile a question layout checklist relevant to the case study above State the overall conclusion of the audit conducted at JESH organisation Produce an audit report stating the nonconformity, type of non-conformance (Critical, Major, Minor), state the clause number/s from the ISO 9001:2008 standard (see annexture 1) that is/are not been followed for each incident. (18) (5) 1.6 In the storage room, stocks of food additives were found to be contaminated by fumes from extraction ducts that were not airtight. (40) Study the non-conformance above and design and complete a corrective/preventive action report form. Page 3 of 3 Note: Complete the root cause of the non-conformance, requirements for effective resolution and proposed action plan to correct the non-conformance. (10) As the QA representative of JESH organisation, management has requested you to compile a resolution report of the non-conformities identified during the audit. Describe to management what action plan would you propose. [101] (10)

Step by Step Solution

★★★★★

3.45 Rating (155 Votes )

There are 3 Steps involved in it

Step: 1

11 Initial Contact with the Auditee The purpose of initial contact with the auditee is to establish communication and rapport clarify the audit objectives and coordinate logistics for the audit Types ...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started