Answered step by step

Verified Expert Solution

Question

1 Approved Answer

table [ [ FROM TO , table [ [ WAREHOUSE ] , [ A ] ] , table [ [ WAREHOUSE ]

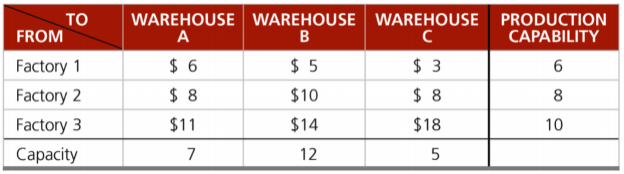

tableFROM TOtableWAREHOUSEAtableWAREHOUSEBtableWAREHOUSECtablePRODUCTIONCAPABILITYFactory $$$Factory $$$Factory $$$CapacityElversberg Manufacturing has three factories and and three warehouses A B and C The following table shows the shipping costs between each factory and warehouse, the factory manufacturing capabilities in thousands and the warehouse capacities in thousands Note that the costs below are not in thousands.

Management would like to keep the warehouses filled to capacity in order to generate demand. Formulate a linear program in order to find the optimal flow of items from factories to

warehouses such that total shipping cost is lowest. Ensure that the constraints of your linear program are such that factories produce at most their production capability and capacity at each warehouse is met exactly. Clearly write out your linear program objective function and constraints in your PDF

Next, use Excels Solver to solve the linear program. Your PDF must state the following: The

optimal solution the values that the decision variables take and the optimal value of the

objective function the value of the objective function at the optimal solution You must also submit an Excel file containing the linear programming formulation. Note that your optimal

objective function value will be in $s since the quantity of items is in s For example, if your solution in Excel is that would mean that the optimal cost is $

Also, answer the following questions in the PDF Hint: the sensitivity report can help you answer the first two questions

The shipping cost from Factory to Warehouse C increases to $ Is the solution that you found above still the optimal solution? How did you decide this?

The firmisinformed that they can increase the production capacity of factory by in s This will cost the firm $ Is it worth it for the firm to increase production

capacity in this manner? Explain how you came to your answer.

In a new Excel sheet in the same file run the same linear program with the following change: Capacity at Warehouse C is increased to in s What does Excel state

when you click Solve at the step where you are prompted to select where to place the results Why is Excel stating this? Ensure that your explanation is clearly addressing

what is happening with production capability and capacity which must be satisfied exactly

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started