Question: Read and analyse the following case study, R&D and Operations: How to Make Them Talk. Then answer the question requirements at the end of

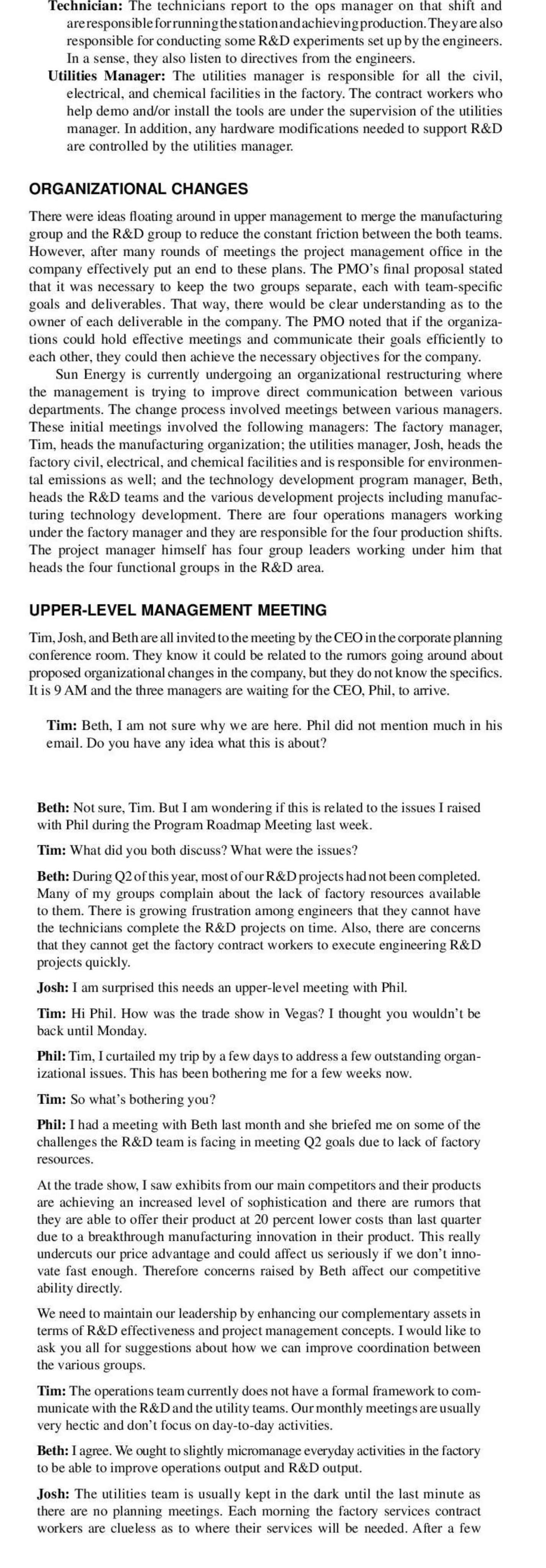

Read and analyse the following case study, "R&D and Operations: How to Make Them Talk". Then answer the question requirements at the end of the case study write-up. Case Study: "R&D and Operations: How to Make Them Talk" 99 by Priya Venugopal. As the CEO, John Phillip needs to meet the commitments of his company to sell 5 million units of the solar panels to the OEMS each quarter for the next two quar- ters. However, the solar technology and industry are growing extremely fast and need rapid improvement in efficiency at lower costs to remain competitive in the market. There are various emerging technologies that are very promising. Some of these include dye-sensitized solar cells, noncrystalline silicon cells, cells based on organic materials, and thin film solar cells using inorganic semiconductors made of elements such as cadmium and tellurium or even copper, indium, gallium, and selenium. Each of these emerging technologies holds the potential to completely destroy Sun Energy's market share by offering various innovative products. It is therefore imperative for Mr. John Phillip to keep the R&D pace extremely brisk in the company. The focus of this case study is organizational structuring, very often used in a process. Its purpose is to define organizational responsibilities and reporting relationships. SUN ENERGY Sun Energy Inc. is a manufacturing company that manufactures and markets high-efficiency silicon Photovoltaic (PV) cells. The manufacturing facility oper- ates 24/7 by employing four shifts of technicians. There is a management chain that oversees only manufacturing operations in this plant. In addition there is a significant amountof R&D work that also occurs in tandem. The R&D management employs many engineers to foresee R&D projects and develop next-generation, higher efficiency solar panels. This team of engineers is also responsible for improving the manufacturing technology for enhancing productivity and reduc- ing cost. The manufacturing and the R&D teams often are at logger heads trying to use the same resources in the factory. There is constant friction between the two managers and the technicians are usually torn between the two objectives set by the two managers. There is immediate need to reduce chaos and improve the communication between the two organizations. The manufacturing teams and the R&D teams are two separate management structures which both are responsible for the profitability of the factory. The technicians are direct reports to the operations manager. However, the technicians are trained by the R&D engineers who also are responsible for maintenance of the factory equipment. The operations manager is responsible for improving the productivity of the factory and increasing total output in a shift. However, R&D work often affects the productivity for that shift and this is another constant source of friction between the manufacturing team and the engineering team. JOB DESCRIPTION The organizational structure of Sun Energy Inc. can be seen in Figure 22.3. Operation Manager: The "ops manager" supervises the technicians in each shift and is responsible for the factory production output during this shift. He reports to the factory manager. There are four ops managers for the four shifts in a week. Factory Manager: This individual is responsible for meeting the factory pro- duction output and reports directly to the CEO of the company. Engineer: The engineers own the production tools and are also the primary drivers of the R&D projects in addition to supporting the performance of the production tools. R&D Manager: The R&D manager supervises the engineers and the overall R&D program for the factory. Figure 22.3 Organizational Structure of Sun Energy Inc. Factory Manager R&D Program Manager Utility Manager Operations Manager Group Leaders Technicians Engineers Technician: The technicians report to the ops manager on that shift and areresponsible forrunningthe stationandachieving production. Theyare also responsible for conducting some R&D experiments set up by the engineers. In a sense, they also listen to directives from the engineers. Utilities Manager: The utilities manager is responsible for all the civil, electrical, and chemical facilities in the factory. The contract workers who help demo and/or install the tools are under the supervision of the utilities manager. In addition, any hardware modifications needed to support R&D are controlled by the utilities manager. ORGANIZATIONAL CHANGES There were ideas floating around in upper management to merge the manufacturing group and the R&D group to reduce the constant friction between the both teams. However, after many rounds of meetings the project management office in the company effectively put an end to these plans. The PMO's final proposal stated that it was necessary to keep the two groups separate, each with team-specific goals and deliverables. That way, there would be clear understanding as to the owner of each deliverable in the company. The PMO noted that if the organiza- tions could hold effective meetings and communicate their goals efficiently to each other, they could then achieve the necessary objectives for the company. Sun Energy is currently undergoing an organizational restructuring where the management is trying to improve direct communication between various departments. The change process involved meetings between various managers. These initial meetings involved the following managers: The factory manager, Tim, heads the manufacturing organization; the utilities manager, Josh, heads the factory civil, electrical, and chemical facilities and is responsible for environmen- tal emissions as well; and the technology development program manager, Beth, heads the R&D teams and the various development projects including manufac- turing technology development. There are four operations managers working under the factory manager and they are responsible for the four production shifts. The project manager himself has four group leaders working under him that heads the four functional groups in the R&D area. UPPER-LEVEL MANAGEMENT MEETING Tim, Josh, and Beth are all invited to the meeting by the CEO in the corporate planning conference room. They know it could be related to the rumors going around about proposed organizational changes in the company, but they do not know the specifics. It is 9 AM and the three managers are waiting for the CEO, Phil, to arive. Tim: Beth, I am not sure why we are here. Phil did not mention much in his email. Do you have any idea what this is about? Beth: Not sure, Tim. But I am wondering if this is related to the issues I raised with Phil during the Program Roadmap Meeting last week. Tim: What did you both discuss? What were the issues? Beth: During Q2 of this year, most of our R&D projects had not been completed. Many of my groups complain about the lack of factory resources available to them. There is growing frustration among engineers that they cannot have the technicians complete the R&D projects on time. Also, there are concerns that they cannot get the factory contract workers to execute engineering R&D projects quickly. Josh: I am surprised this needs an upper-level meeting with Phil. Tim: Hi Phil. How was the trade show in Vegas? I thought you wouldn't be back until Monday. Phil: Tim, I curtailed my trip by a few days to address a few outstanding organ- izational issues. This has been bothering me for a few weeks now. Tim: So what's bothering you? Phil: I had a meeting with Beth last month and she briefed me on some of the challenges the R&D team is facing in meeting Q2 goals due to lack of factory resources. At the trade show, I saw exhibits from our main competitors and their products are achieving an increased level of sophistication and there are rumors that they are able to offer their product at 20 percent lower costs than last quarter due to a breakthrough manufacturing innovation in their product. This really undercuts our price advantage and could affect us seriously if we don't inno- vate fast enough. Therefore concerns raised by Beth affect our competitive ability directly. We need to maintain our leadership by enhancing our complementary assets in terms of R&D effectiveness and project management concepts. I would like to ask you all for suggestions about how we can improve coordination between the various groups. Tim: The operations team currently does not have a formal framework to com- municate with the R&Dand the utility teams. Our monthly meetings are usually very hectic and don't focus on day-to-day activities. Beth: I agree. We ought to slightly micromanage everyday activities in the factory to be able to improve operations output and R&D output. Josh: The utilities team is usually kept in the dark until the last minute as there are no planning meetings. Each morning the factory services contract workers are clue less as to where their services will be needed. After a few hours into the day, requests pour in from operations and R&D and often clash and make it very ineffective. We should have better coordination. Tim: Can the operations and the R&D teams meet each morning and coordi- nate their work to allocate utility worker resources and technician priorities? We had tried it once in the past and it worked reasonably well. Beth: That sounds like a good idea. I think that would give the engineering team a chance to plan their experiments in advance and give a proposal to the operations team. Phil: In the past what were the reasons why these meetings stopped being effective? Beth: Often there was no understanding of the R&D roadmap versus The oper- ations roadmap. It was difficult for the teams to understand the priorities of the other team and how it related to the "critical few" mandated by the company. We stopped having daily meetings as it turned out to be an ineffective forum to understand each other's priorities. Josh: Maybe we can have an upper management planning group that can over- see the long-term priorities and goals of various groups in the company. Phil: That sounds like a good idea. I recommend creating a project oversight committee involving the R&D manager, utilities manager, and the factory manager. They should meet once every two weeks to discuss project roadmaps in each of these groups. I will also attend this meeting to align the company's long-term goals with the short-term milestones in each of these groups. Tim: I also suggest having a daily meeting attended by the ops manager for that shift and a few engineers from across various engineering teams to deter- mine daily priorities for the technicians and the factory resources. Beth: That sounds good. Between the fortnightly meetings and daily meetings, we should be able to coordinate better between the R&D and operations teams. I will set up these meetings and send out outlook requests. Thank you all for your inputs in addressing these issues. Question Requirements: What are the pros and cons if Phil decides to merge the operations and R&D units? Discuss thoroughly. Summarize Sun Energy's plan to improve coordination beween operations and R&D and discuss the advantages and the disadvantages of such a plan. Thoroughly explain. What should be the roles and responsibilities of the project oversight committee? Explain. 1. 2. 3.

Step by Step Solution

3.47 Rating (157 Votes )

There are 3 Steps involved in it

1 The pros if Phil decides to merge the operations and RD units are as follows a The operations and ... View full answer

Get step-by-step solutions from verified subject matter experts