Question

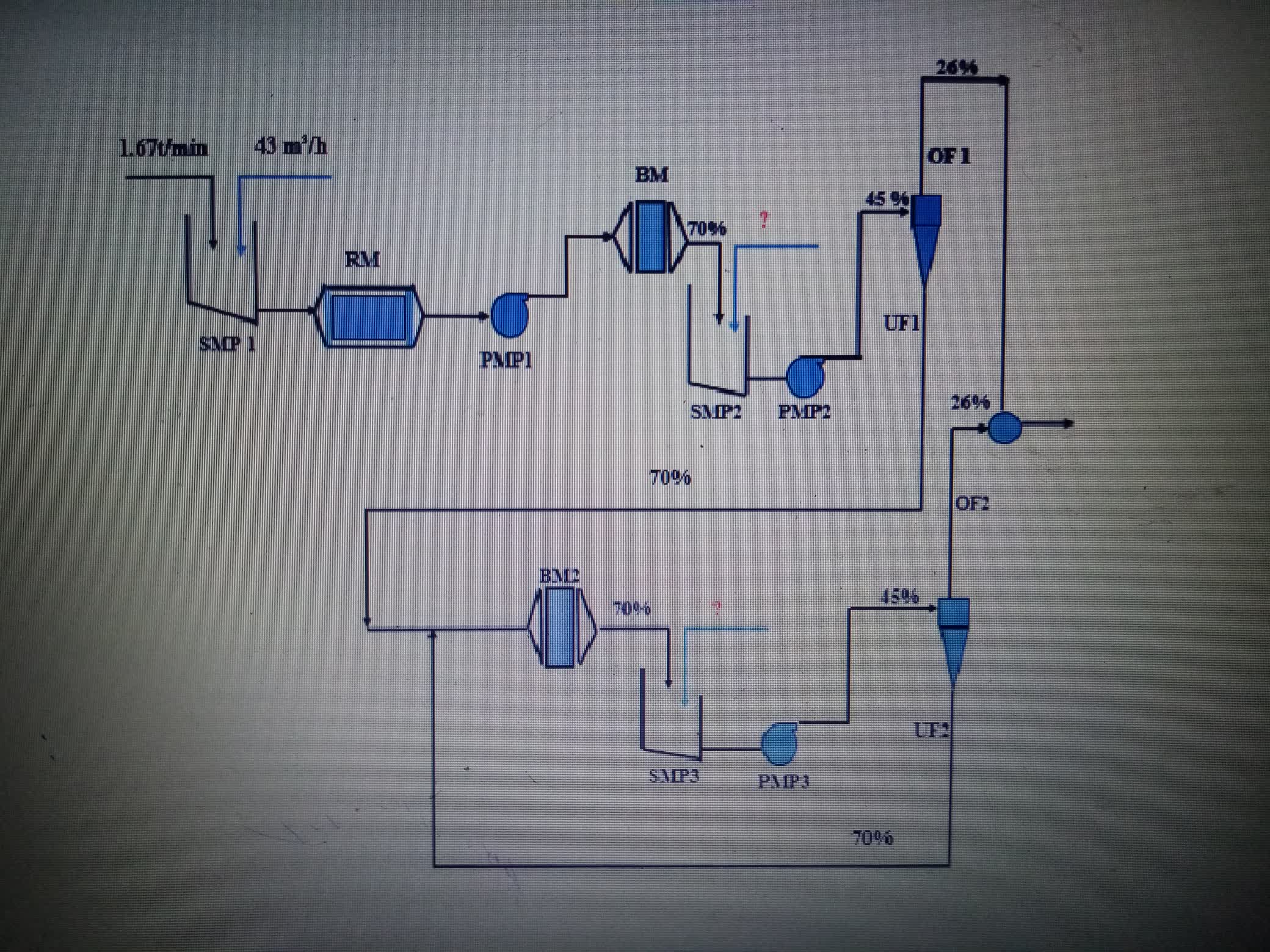

The Figure 2 represents a conventional milling circuit at Palabora Mining. Crushed copper ore of -9 mm particle size is fed to the rod mill,

The Figure 2 represents a conventional milling circuit at Palabora Mining. Crushed copper ore of -9 mm particle size is fed to the rod mill, and the water is fed in ratio to the ore feed mass of solids density 2.560 t/m3. The rod mill discharge is pumped, without any further water addition, to the first ball mill. The ball mill discharges to a sump where water is added before the slurry is pumped to the first cyclone (Cyclone 1). The slurry stream is classified at Cyclone 1 with the overflow going to the flotation circuit. Cyclone 1 underflow constitutes the fresh feed to the second milling circuit that runs in a closed circuit with its own cyclone (Cyclone 2). Ball mill 2 discharges to a sump where water is added before the slurry is pumped to Cyclone 2. Cyclone 2 overflow gravitates to a distributor and is combined with Cyclone 1 overflow before gravitating to the flotation circuit. Cyclone 2 underflow circulates back to Ball Mill 2. The final product of the milling circuit is sent to the concentration circuit consisting of flotation cell banks as shown in Figure 3. The chemical compositions of the froth flotation streams are shown in Table 3. The mass flowrate of the concentrate produced at the concentration circuit is highly dependent on the frother dosage

Table 2: Legend Figure 2 RM: Rod Mill BM: Ball Mill SMP: Sump PMP: Pump OF: Overflow UF: Underflow

Questions

1.Determine the circulating load ratio for ball mill BM2.

2.Water addition at the sump 3 in ((m^3)/h)

3.Percentage solids in the slurry sent to the flotation circuit.

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started