Answered step by step

Verified Expert Solution

Question

1 Approved Answer

The following considers the exponential distribution. In a chemical plant, there is a machine equipped with a tank used to boil a chemical product. The

The following considers the exponential distribution.

In a chemical plant, there is a machine equipped with a tank used to boil a chemical product. The chemical product, in its liquid form, poses no danger to the operator. However, when it turns into vapor, it becomes lethal.

The machine is operated for two hour shifts per day, during which the chemical substance is boiled, placing the tank under pressure. The company operates this machine days a week, for weeks a year.

One worker is required to be present in the room for hours at the start of each shift to set up and initiate the process, and for hour at the end to securely shut it down. During the first hour of the hour setup period, the worker prepares the tank, fills it with the chemical product, and starts the machine. The boiling of the product begins hour after the machine is turned on which is hours from the start of the shift. The worker must remain in the room for an additional hours after the machine has started, totaling hours at the beginning of each shift. The worker then returns hour before the end of the shift to stop the machine. For simplicity, assume that the boiling process stops hour before the end of the shift.

The critical safety concern is the potential leakage of the chemical vapor into the room, which would be lethal if inhaled by the worker. Note that the worker cannot wear any protective equipment. However, the worker has a reaction time of minutes if aware of the vapors starting to being released, which is sufficient to leave the room if an alarm is triggered.

The proposed safety measure is the installation of a vapor detector that triggers an alarm if any vapor is released. Given that the gas is odorless and colorless, this safety device aims to reduce the risk level to a tolerable level, defined as no more than fatalities.

Question : Determine the Safety Integrity Level SIL required for this device based on the given scenario?

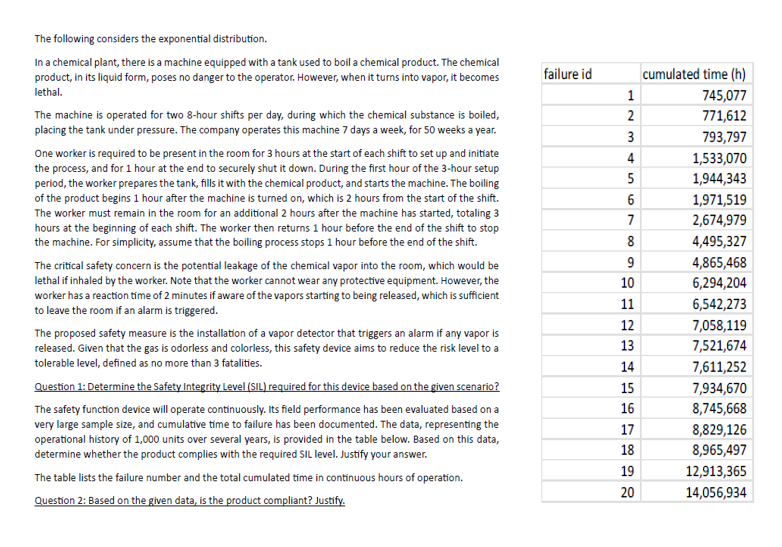

The safety function device will operate continuously. Its field performance has been evaluated based on a very large sample size, and cumulative time to failure has been documented. The data, representing the operational history of units over several years, is provided in the table below. Based on this data, determine whether the product complies with the required SIL level. Justify your answer.

The table lists the failure number and the total cumulated time in continuous hours of operation.

Question : Based on the given data, is the product compliant? Justify.

tablefailure idcumulated time h

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started