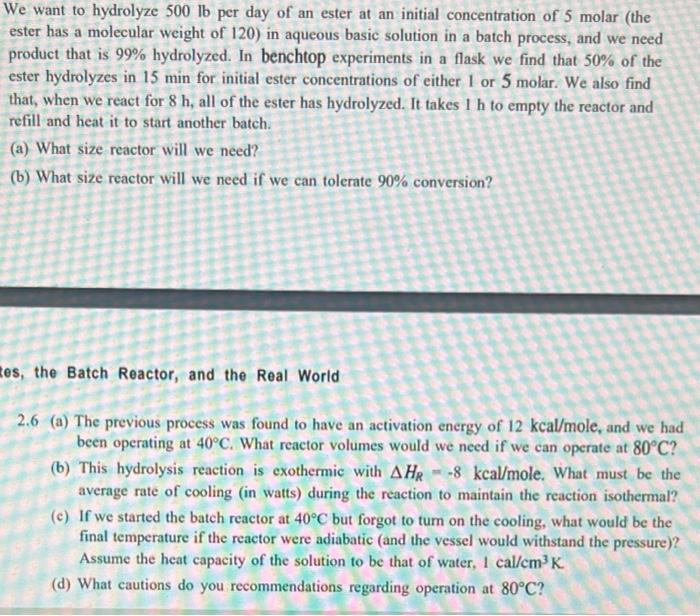

We want to hydrolyze 500 lb per day of an ester at an initial concentration of 5 molar (the ester has a molecular weight of 120) in aqueous basic solution in a batch process, and we need product that is 99% hydrolyzed. In benchtop experiments in a flask we find that 50% of the ester hydrolyzes in 15 min for initial ester concentrations of either 1 or 5 molar. We also find that, when we react for 8 h, all of the ester has hydrolyzed. It takes 1 h to empty the reactor and refill and heat it to start another batch. (a) What size reactor will we need? (b) What size reactor will we need if we can tolerate 90% conversion? tes, the Batch Reactor, and the Real World 2.6 (a) The previous process was found to have an activation energy of 12 kcal/mole, and we had been operating at 40C. What reactor volumes would we need if we can operate at 80C? (b) This hydrolysis reaction is exothermic with A HR - -8 kcal/mole. What must be the average rate of cooling (in watts) during the reaction to maintain the reaction isothermal? (c) If we started the batch reactor at 40C but forgot to tum on the cooling, what would be the final temperature if the reactor were adiabatic (and the vessel would withstand the pressure)? Assume the heat capacity of the solution to be that of water, I cal/cmK. (d) What cautions do you recommendations regarding operation at 80C? We want to hydrolyze 500 lb per day of an ester at an initial concentration of 5 molar (the ester has a molecular weight of 120) in aqueous basic solution in a batch process, and we need product that is 99% hydrolyzed. In benchtop experiments in a flask we find that 50% of the ester hydrolyzes in 15 min for initial ester concentrations of either 1 or 5 molar. We also find that, when we react for 8 h, all of the ester has hydrolyzed. It takes 1 h to empty the reactor and refill and heat it to start another batch. (a) What size reactor will we need? (b) What size reactor will we need if we can tolerate 90% conversion? tes, the Batch Reactor, and the Real World 2.6 (a) The previous process was found to have an activation energy of 12 kcal/mole, and we had been operating at 40C. What reactor volumes would we need if we can operate at 80C? (b) This hydrolysis reaction is exothermic with A HR - -8 kcal/mole. What must be the average rate of cooling (in watts) during the reaction to maintain the reaction isothermal? (c) If we started the batch reactor at 40C but forgot to tum on the cooling, what would be the final temperature if the reactor were adiabatic (and the vessel would withstand the pressure)? Assume the heat capacity of the solution to be that of water, I cal/cmK. (d) What cautions do you recommendations regarding operation at 80C