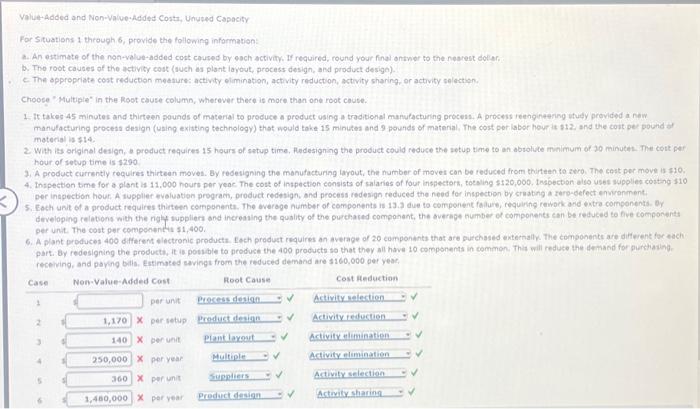

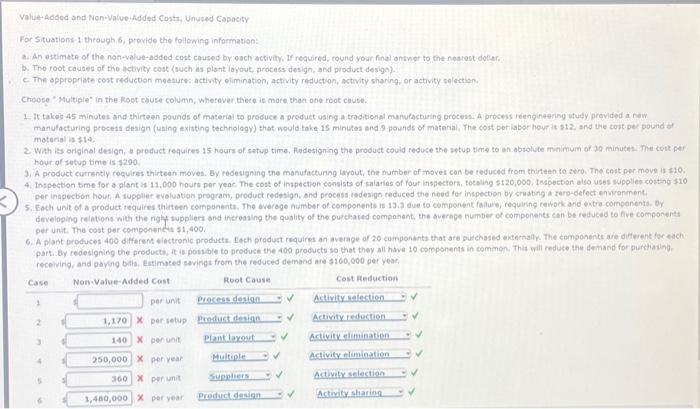

Wolue-Added and Non-vaive-Hdded Costr, Unuted Capacity For situations 1 through 6 , provide the following information: a. An estimate of the non-value-added cost coused by each activity. If required, round your final ontwor to the nearest doliar. b. The root cavees of the activity cost (auch as plant laybut, process design, and product desigo) c. The appropriate cost reduction meature: activity elimination, activity reduction, Activity sharing, or activity selection. Chioose "Multiple" in the Root cause column, wherewer thece is more than ond root caute. 1. It takes 45 minutes and thirteen pounds of material to produce a product using a traditional manufacturing procens. A procesis reenginaering utucy provided a new. manufacturing process design (uaing existing technology) that pould take 15 minutes and 9 pounds of material, The cost per labor heur it st2. and the coit per pound of materigl is $14. 2. With its original design, a preduct requires 15 hours of setup time, thedesigning the product could reduce the setup time to an abrolute invilimum of 20 minutht. The cott per hour of setup time is 1290 2. A product currently requires thirteen moves. By redesigning the monufacturing layout, the number of movet can be reductid from thirtean to ztro. The cest per move is t1o: 4. Inspection bme for a plant is 11,000 hours per veoc. The cost of inspection consists of salaries of four inspectors, tocalihg 5120 , 0oo. tespecten alio uses suppliet couthg 110 per inspecbon hout. A supplier evoluatien prograch, product redtsign, and process redesign reduced the need tor inspectoon by sriating a zero-defect envyropent. 5. Foch unit of a prodoct requires thirtese compenanta. The overege number of components in 13.2 due to component failure, requirhe rework and entre compenents. 0y developing relations with the ngly suppliers ond increating the quality of the purchaced compohant, the sverage number of components can be reduced to five componenta per unit. The cost per compenente 11,400. 6. A plant produces 400 different electronic producta. Each product requires an average of 20 componanta thot are purchased enternaily. The componente are different foc each part: By redesigning the producti, it is powible to product the 400 products so that they ail have 10 components in common. Thit will reduce the detinacid for purthasing. receling, and paying billa. Estimbeed savingt from the reduced demand are 1160,000 oet yeac. Wolue-Added and Non-vaive-Hdded Costr, Unuted Capacity For situations 1 through 6 , provide the following information: a. An estimate of the non-value-added cost coused by each activity. If required, round your final ontwor to the nearest doliar. b. The root cavees of the activity cest (auch as plant laybut, process design, and product desigo) c. The appropriate cost reduction meature: activity elimination, activity reduction, Activity sharing, or activity selection. Chioose "Multiple" in the Root cause column, wherewer thece is more than ond root caute. 1. It takes 45 minutes and thirteen pounds of material to produce a product using a traditional manufacturing procens. A procesis reenginaering utucy provided a new. manufacturing process design (uaing existing technology) that pould take 15 minutes and 9 pounds of material, The cost per labor heur it st2. and the coit per pound of materigl is $14. 2. With its original design, a preduct requires 15 hours of setup time, thedesigning the product could reduce the setup time to an abrolute invilimum of 20 minutht. The cott per hour of setup time is 1290 2. A product currently requires thirteen moves. By redesigning the monufacturing layout, the number of movet can be reductid from thirtean to ztro. The cest per move is t1o: 4. Inspection bme for a plant is 11,000 hours per veoc. The cost of inspection consists of salaries of four inspectors, tocalihg 5120 , 0oo. tespecten alio uses suppliet couthg 110 per inspecbon hout. A supplier evoluatien prograch, product redtsign, and process redesign reduced the need tor inspectoon by sriating a zero-defect envyropent. 5. Foch unit of a prodoct requires thirtese compenanta. The overege number of components in 13.2 due to component failure, requirhe rework and entre compenents. 0y developing relations with the ngly suppliers ond increating the quality of the purchaced compohant, the sverage number of components can be reduced to five componenta per unit. The cost per compenente 11,400. 6. A plant produces 400 different electronic producta. Each product requires an average of 20 componanta thot are purchased enternaily. The componente are different foc each part: By redesigning the producti, it is powible to product the 400 products so that they ail have 10 components in common. Thit will reduce the detinacid for purthasing. receling, and paying billa. Estimbeed savingt from the reduced demand are 1160,000 oet yeac. Wolue-Added and Non-vaive-Hdded Costr, Unuted Capacity For situations 1 through 6 , provide the following information: a. An estimate of the non-value-added cost coused by each activity. If required, round your final ontwor to the nearest doliar. b. The root cavees of the activity cost (auch as plant laybut, process design, and product desigo) c. The appropriate cost reduction meature: activity elimination, activity reduction, Activity sharing, or activity selection. Chioose "Multiple" in the Root cause column, wherewer thece is more than ond root caute. 1. It takes 45 minutes and thirteen pounds of material to produce a product using a traditional manufacturing procens. A procesis reenginaering utucy provided a new. manufacturing process design (uaing existing technology) that pould take 15 minutes and 9 pounds of material, The cost per labor heur it st2. and the coit per pound of materigl is $14. 2. With its original design, a preduct requires 15 hours of setup time, thedesigning the product could reduce the setup time to an abrolute invilimum of 20 minutht. The cott per hour of setup time is 1290 2. A product currently requires thirteen moves. By redesigning the monufacturing layout, the number of movet can be reductid from thirtean to ztro. The cest per move is t1o: 4. Inspection bme for a plant is 11,000 hours per veoc. The cost of inspection consists of salaries of four inspectors, tocalihg 5120 , 0oo. tespecten alio uses suppliet couthg 110 per inspecbon hout. A supplier evoluatien prograch, product redtsign, and process redesign reduced the need tor inspectoon by sriating a zero-defect envyropent. 5. Foch unit of a prodoct requires thirtese compenanta. The overege number of components in 13.2 due to component failure, requirhe rework and entre compenents. 0y developing relations with the ngly suppliers ond increating the quality of the purchaced compohant, the sverage number of components can be reduced to five componenta per unit. The cost per compenente 11,400. 6. A plant produces 400 different electronic producta. Each product requires an average of 20 componanta thot are purchased enternaily. The componente are different foc each part: By redesigning the producti, it is powible to product the 400 products so that they ail have 10 components in common. Thit will reduce the detinacid for purthasing. receling, and paying billa. Estimbeed savingt from the reduced demand are 1160,000 oet yeac. Wolue-Added and Non-vaive-Hdded Costr, Unuted Capacity For situations 1 through 6 , provide the following information: a. An estimate of the non-value-added cost coused by each activity. If required, round your final ontwor to the nearest doliar. b. The root cavees of the activity cest (auch as plant laybut, process design, and product desigo) c. The appropriate cost reduction meature: activity elimination, activity reduction, Activity sharing, or activity selection. Chioose "Multiple" in the Root cause column, wherewer thece is more than ond root caute. 1. It takes 45 minutes and thirteen pounds of material to produce a product using a traditional manufacturing procens. A procesis reenginaering utucy provided a new. manufacturing process design (uaing existing technology) that pould take 15 minutes and 9 pounds of material, The cost per labor heur it st2. and the coit per pound of materigl is $14. 2. With its original design, a preduct requires 15 hours of setup time, thedesigning the product could reduce the setup time to an abrolute invilimum of 20 minutht. The cott per hour of setup time is 1290 2. A product currently requires thirteen moves. By redesigning the monufacturing layout, the number of movet can be reductid from thirtean to ztro. The cest per move is t1o: 4. Inspection bme for a plant is 11,000 hours per veoc. The cost of inspection consists of salaries of four inspectors, tocalihg 5120 , 0oo. tespecten alio uses suppliet couthg 110 per inspecbon hout. A supplier evoluatien prograch, product redtsign, and process redesign reduced the need tor inspectoon by sriating a zero-defect envyropent. 5. Foch unit of a prodoct requires thirtese compenanta. The overege number of components in 13.2 due to component failure, requirhe rework and entre compenents. 0y developing relations with the ngly suppliers ond increating the quality of the purchaced compohant, the sverage number of components can be reduced to five componenta per unit. The cost per compenente 11,400. 6. A plant produces 400 different electronic producta. Each product requires an average of 20 componanta thot are purchased enternaily. The componente are different foc each part: By redesigning the producti, it is powible to product the 400 products so that they ail have 10 components in common. Thit will reduce the detinacid for purthasing. receling, and paying billa. Estimbeed savingt from the reduced demand are 1160,000 oet yeac