A commercial steel class 300 schedule 40 pipe is being used to transport 1000 gpm of liquid

Question:

A commercial steel class 300 schedule 40 pipe is being used to transport 1000 gpm of liquid cyclohexane at 70°F. The fittings, valves, supports, and pump are estimated to cost 6.9 times the amortized installed pipe cost per ft. Annual maintenance is estimated to be 2% of the amortized installed pipe costs per ft.

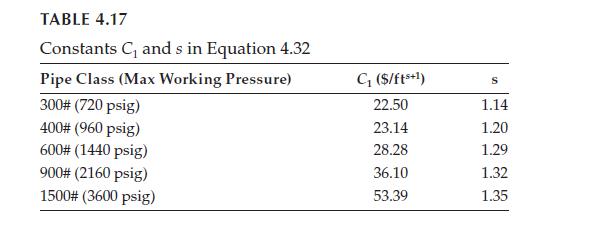

The pump in the system runs 12 hours per day, 260 days per year. The efficiency of the pump is estimated to be 68%. The cost of energy is $0.09/kW-h. The pipeline is expected to have a 50-year life and a rate of return of 20%. Use an inflation rate of 1.5% to adjust the value of C1 from Table 4.17 to 2012 dollars.

a. Determine the economic diameter and specify the standard pipe size that results in the minimum system cost.

b. Determine the economic velocity of the fluid (ft/s).

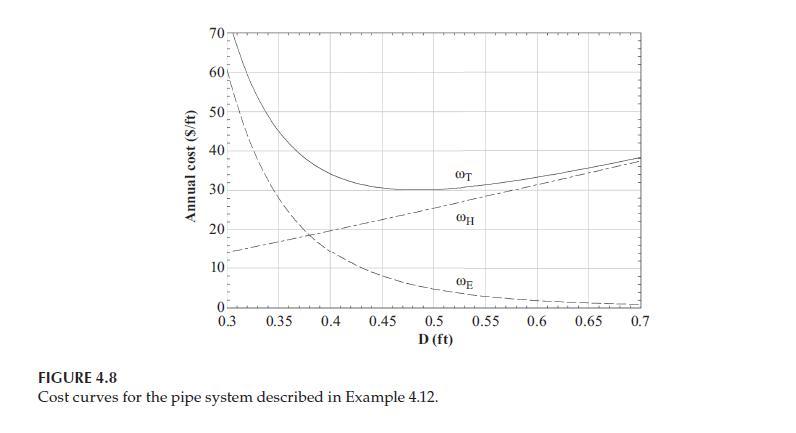

c. Construct the cost curves for this scenario assuming that the friction factor can be assumed constant at the value computed for the economic diameter from part (a). Your plot should look similar to Figure 4.8.

Step by Step Answer:

Thermal Energy Systems Design And Analysis

ISBN: 9781138735897

2nd Edition

Authors: Steven G. Penoncello