Injection molding is a manufacturing process in which a mold is filled with a liquid that solidifies

Question:

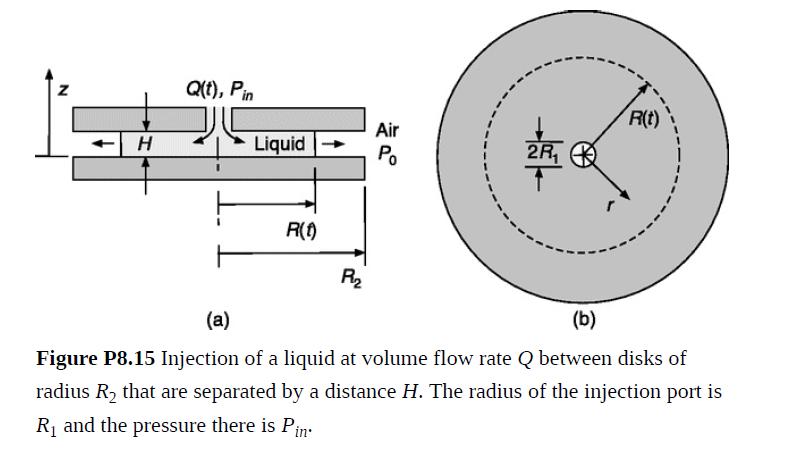

Injection molding is a manufacturing process in which a mold is filled with a liquid that solidifies after cooling. The mold is then opened and the product removed. Such molds have openings for injecting the liquid and venting the displaced air. Consider the simple prototype in Fig. P8.15, in which the space to be filled is a gap of thickness H between disks of radius R2. Applying a constant pressure Pin at an injection port of radius R1 in one of the disks results in a volume flow rate Q(t). The radius of the filled region at a given instant is R(t). Assume that the flow is pseudosteady, that inertia, surface tension, and gravity are all negligible, and that R2 ≫ R1 or H. It is desired to relate the filling time tf to the pressure drop |ΔP| = Pin − P0, the viscosity, and the linear dimensions.

(a) Relate the height-averaged radial velocity ![]()

to Q(t) and the dimensions.

(b) Solve for vr(r, z, t) in terms of ∂P/∂r.

(c) Evaluate ∂P/∂r and relate Q(t) to |ΔP| and R(t).

(d) Obtain the differential equation that governs R(t) and find the relationship between tf and |ΔP|.

(e) Approximately how large must tf be to justify the pseudosteady approximation?

Step by Step Answer:

Introduction To Chemical Engineering Fluid Mechanics

ISBN: 9781107123779

1st Edition

Authors: William M. Deen