Answered step by step

Verified Expert Solution

Question

1 Approved Answer

h I want a detailed solution , PLEASE WATER TREATMENT PLANT PROCESS COSTS there was neither aeration nor recirculation. For turbidity, the Background reduction was

h

h

I want a detailed solution , PLEASE

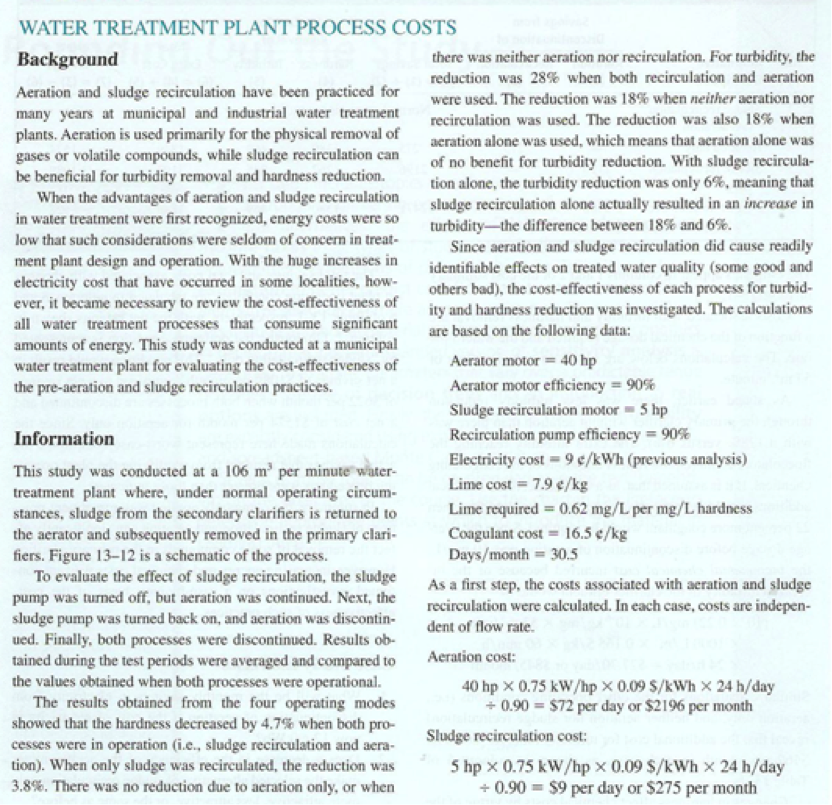

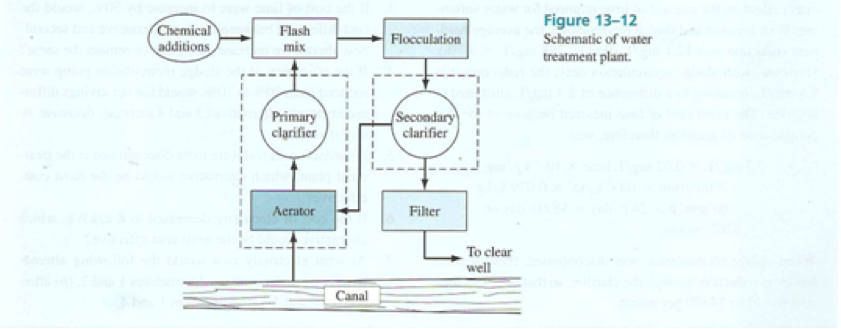

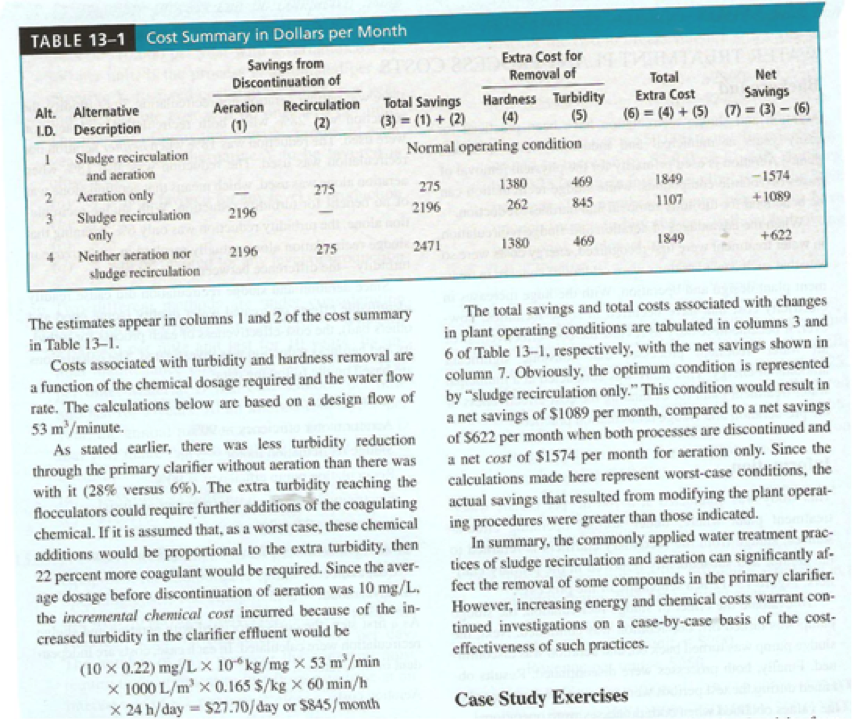

WATER TREATMENT PLANT PROCESS COSTS there was neither aeration nor recirculation. For turbidity, the Background reduction was 28% when both recirculation and aeration Aeration and sludge recirculation have been practiced for were used. The reduction was 18% when neilher aeration nor many years at municipal and industrial water treatment recirculation was used. The reduction was also 18% when plants, Aeration is used primarily for the physical removal of aeration alone was used, which means that acration alone was gases or volatile compounds, while sludge recirculation can of no benefit for turbidity reduction With sludge recircula- be beneficial for turbidity removal and hardness reduction. ion alone, the turbidity reduction was only 6%, meaning that When the advantages of aeration and sludge recirculation sludge recirculation alone actually resulted in an increase in in water treatment were first recognized, energy costs were so turbidity-the difference between 18% and 6% low that such considerations were seldom of concem in treat- Since aeration and sludge recirculation did cause readily ment plant design and operation. With the huge increases in identifiable effects on treated water quality (some good and electricity cost that have occurred in some localities, how- others bad), the cost-effectiveness of each process forturbid- ever, it became necessary to review the cost-effectivene ty and hardness reduction was investigated. The calculations all water treatment processes that consume significant are based on the following dat amounts of energy. This study was conducted a a municipal Aerator motor 40 hp water treatment plant for evaluating the cost-effectiveness of Aerator motor efficiency- 90% the pre-aeration and sludge recirculation practices Sludge recirculation motor 5 hp Recirculation pump efficiency 90% Information Electricity cost 9e (previous analysis) This study was conducted at a 106 m per minute water Lime cost 7.9 e/kg treatment plant where, under normal operating circum- Lime required 0.62 mg/Lper mg/Lhardness stances, sludge from the secondary clarifiers is returned to Coagulant cost 16.5 e/kg the aerator and subsequently removed in the primary clari Days/month 30.5 fiers. Figure 13-12 is a schematic of the process To evaluate the effect of sludge recirculation, the sludge As a first step, the costs associated with aeration and sludge pump was turned off but aeration was continued. Next, t recirculation were calculated. In each case. costs are i sludge pump was turned back on, and aeration was discontin dent of flow rate. ued. Finally, both processes were discontinued. Results ob- Aeration cost tained during the test periods were averaged and compared to the values obtained when both processes were operational. 40 hp x 0.75 kW/hp x 0.09 $/kWh x 24 h/day The results obtained from the four operating modes 0.90 S72 per day or $2196 per month showed that the hardness decreased by 4.7% when both pro- Sludge recirculation cost: cesses were in operation (i.e., sludge recirculation and aera 5 hp x 0.75 kW/hp x 0.09$/kWh x 24 h/day tion). When only sludge was recirculated, the reduction was 0.90 S9 per day or S275 per month 3.8%. There was no reduction due to aeration only, or when WATER TREATMENT PLANT PROCESS COSTS there was neither aeration nor recirculation. For turbidity, the Background reduction was 28% when both recirculation and aeration Aeration and sludge recirculation have been practiced for were used. The reduction was 18% when neilher aeration nor many years at municipal and industrial water treatment recirculation was used. The reduction was also 18% when plants, Aeration is used primarily for the physical removal of aeration alone was used, which means that acration alone was gases or volatile compounds, while sludge recirculation can of no benefit for turbidity reduction With sludge recircula- be beneficial for turbidity removal and hardness reduction. ion alone, the turbidity reduction was only 6%, meaning that When the advantages of aeration and sludge recirculation sludge recirculation alone actually resulted in an increase in in water treatment were first recognized, energy costs were so turbidity-the difference between 18% and 6% low that such considerations were seldom of concem in treat- Since aeration and sludge recirculation did cause readily ment plant design and operation. With the huge increases in identifiable effects on treated water quality (some good and electricity cost that have occurred in some localities, how- others bad), the cost-effectiveness of each process forturbid- ever, it became necessary to review the cost-effectivene ty and hardness reduction was investigated. The calculations all water treatment processes that consume significant are based on the following dat amounts of energy. This study was conducted a a municipal Aerator motor 40 hp water treatment plant for evaluating the cost-effectiveness of Aerator motor efficiency- 90% the pre-aeration and sludge recirculation practices Sludge recirculation motor 5 hp Recirculation pump efficiency 90% Information Electricity cost 9e (previous analysis) This study was conducted at a 106 m per minute water Lime cost 7.9 e/kg treatment plant where, under normal operating circum- Lime required 0.62 mg/Lper mg/Lhardness stances, sludge from the secondary clarifiers is returned to Coagulant cost 16.5 e/kg the aerator and subsequently removed in the primary clari Days/month 30.5 fiers. Figure 13-12 is a schematic of the process To evaluate the effect of sludge recirculation, the sludge As a first step, the costs associated with aeration and sludge pump was turned off but aeration was continued. Next, t recirculation were calculated. In each case. costs are i sludge pump was turned back on, and aeration was discontin dent of flow rate. ued. Finally, both processes were discontinued. Results ob- Aeration cost tained during the test periods were averaged and compared to the values obtained when both processes were operational. 40 hp x 0.75 kW/hp x 0.09 $/kWh x 24 h/day The results obtained from the four operating modes 0.90 S72 per day or $2196 per month showed that the hardness decreased by 4.7% when both pro- Sludge recirculation cost: cesses were in operation (i.e., sludge recirculation and aera 5 hp x 0.75 kW/hp x 0.09$/kWh x 24 h/day tion). When only sludge was recirculated, the reduction was 0.90 S9 per day or S275 per month 3.8%. There was no reduction due to aeration only, or whenStep by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started