Answered step by step

Verified Expert Solution

Question

1 Approved Answer

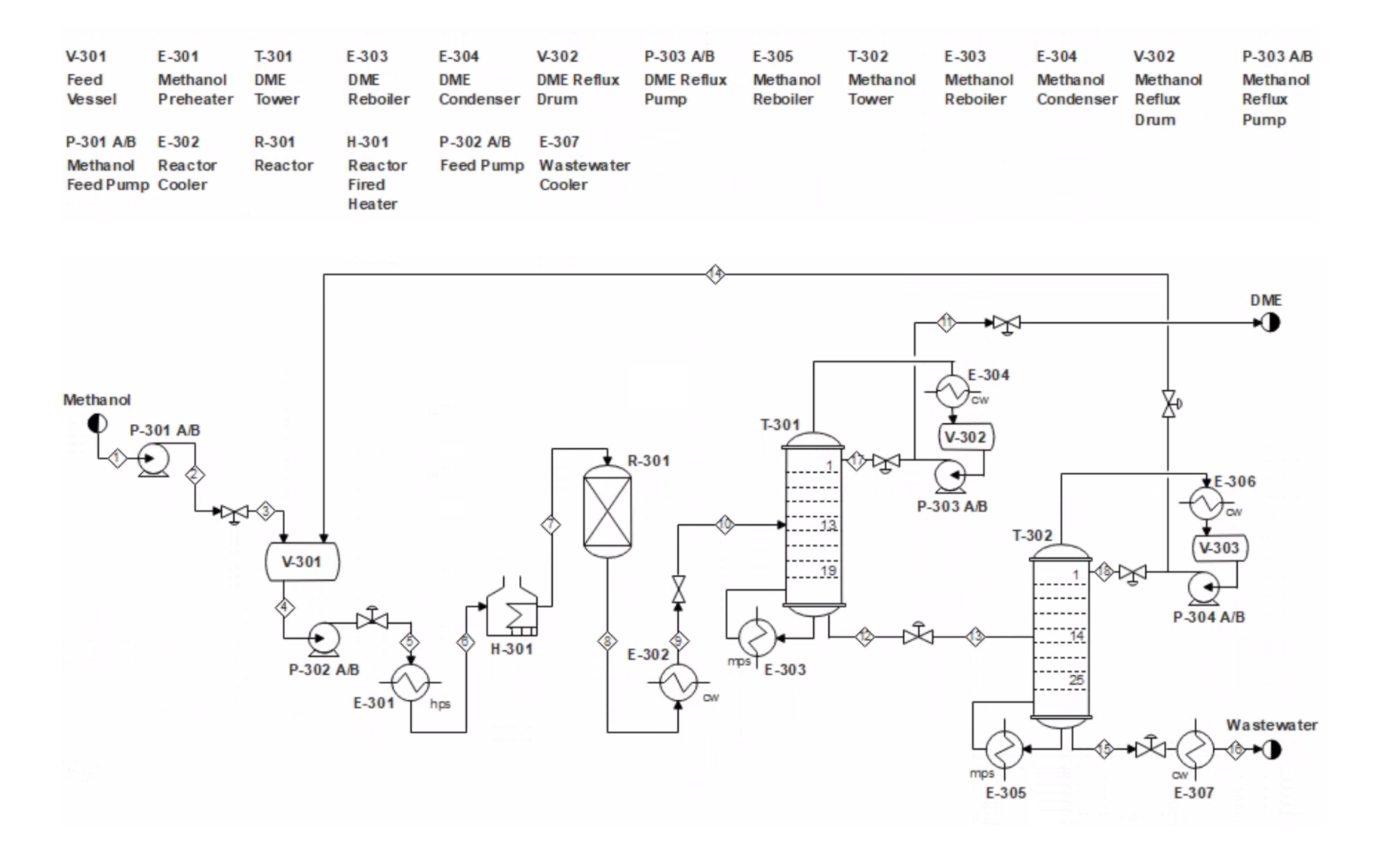

How can this chemical plant be optimized? A preliminary process flow diagram for a DME process is shown in Figure 3 , in which 7

How can this chemical plant be optimized?

A preliminary process flow diagram for a DME process is shown in Figure in which metric tons per year of mol purity DME product is produced. Due to the simplicity of the process, an operating factor greater than hy is used. Methanol, obtained from Unit is combined with recycled reactant and vaporized prior to being sent to a fixedbed reactor. The reactor is operated between deg C and deg C at a pressure of approximately bar. The singlepass conversion of methanol in the reactor is

expected to be between and The reactor effluent is then cooled prior to being sent to the first of two distillation columns: T and T DME product is take overhead from the first column. The second column separates the water from the unused methanol. The methanol is recycled back to the front end of the process, and the water is sent to wastewater treatment to remove trace amounts of organic compounds.

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started