Answered step by step

Verified Expert Solution

Question

1 Approved Answer

please respond to questions 2,3 Design for Supply Chain Programs_ disruption of design and technology changes as products Deign for Supply Chain (DFSC is a

please respond to questions 2,3

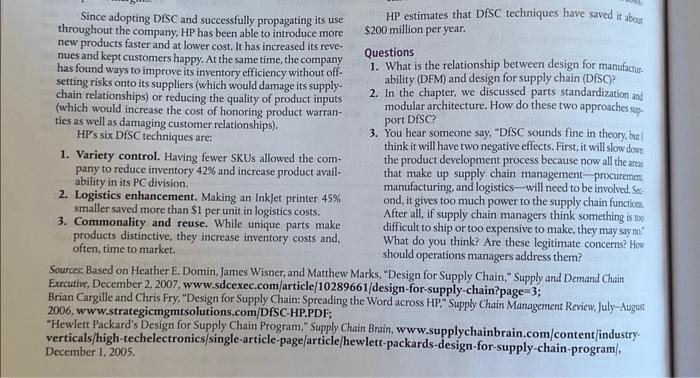

Design for Supply Chain Programs_ disruption of design and technology changes as products Deign for Supply Chain (DFSC is a systematic method of ensuring the best fit between the design of a product through- 5. Build supply chains based on the company's strategic out its lifetime and its supply chain members' resources and plan, not around the idiosyncratic requirements of speappbillties. Even something as simple as flattening the tops of cific products. soda cans, as beverage makers did in the 1950s, can revolution- 6. Use common components and modular design, thereby are product development, transform transportation and invenreducing product variability. 7. Minimize inventory costs and reduce the risk of obsolessory processes, and generate huge cost savings and increased customer satisfaction. Hewlett-Packard (HP) has been in the cence by building to order from common components and subassemblies, rather than building to stock. forcfront of adopting DFSC principles, and IBM is another 8. Design products to give customers flexibility when orderstanch proponent. ing while keeping costs in line. IBM developed a short list of DFSC principles that have 9. Use high quality parts and parts which can be quickly helped it create products that are both competitive and supplydiagnosed to minimize warranty costs and improve after chain-efficient throughout their life cycles. Briefly stated, these sales service. 1. Integrate products parts and components as much as pos- HP similarly uses DiSC to consider the impact of its design principles are: sible to reduce product assembly time. 2. Use industry-standard parts whenever possible to lower duction to end of life cycle, in all its business units and regions. The DSC strategy-essentially looking back in order to see 3. Reduce lead times on critical components to avoid paying ahead-helps improve HPs relationships with suppliers, manpremium shipping fees on rush orders. 4. Design products for supply-chain friendliness throughout asks four questions about its products: their life cycle, planning for and minimizing the cost and Since adopting DFSC and successfully propagating its use HP estimates that DFSC techniques have saved it aboet throughout the company, HP has been able to introduce more $200 million per year. new products faster and at lower cost. It has increased its revenues and kept customers happy. At the same time, the company Questions has found ways to improve its inventory efficiency without off- 1. What is the relationship between design for manufactur. setting risks onto its suppliers (which would damage its supplyability (DFM) and design for supply chain (DFSC? chain relationships) or reducing the quality of product inputs 2. In the chapter, we discussed parts standardization and (which would increase the cost of honoring product warranmodular architecture. How do these two approaches sop. ties as well as damaging customer relationships). port DFSC? HP's six DFSC techniques are: 3. You hear someone say, "DFSC sounds fine in theory, bur 1. Variety control. Having fewer SKUS allowed the comthink it will have two negative effects. First, it will slow down the product development process because now all the area pany to reduce inventory 42% and increase product availability in its PC division. that make up supply chain management-procuremen 2. Logistics enhancement. Making an Inkjet printer 45% ond, it gives too much power to the supply chain function. 3. Commonality and reuse. While unique parts make After all, if supply chain managers think something is too products distinctive, they increase inventory costs and, difficult to ship or too expensive to make, they may say mo" often, time to market. What do you think? Are these legitimate concerns? How should operations managers address them? Sources, Based on Heather E. Domin, James Wisner, and Matthew Marks, "Design for Supply Chain," Supply and Demand Chain Executive, December 2, 2007, www.sdcexec.com/article/10289661/design-for-supply-chain?page=3; Brian Cargille and Chris Fry, "Design for Supply Chain: Spreading the Word across HP," Supply Chain Management Review, July-Augus 2006, www.strategicmgmtsolutions.com/DFSC-HP.PDF; "Hewlett Packard's Design for Supply Chain Program," Supply Chain Brain, www.supplychainbrain.com/content/industry. verticals/high-techelectronics/single-article-page/article/hewlett-packards-design-for-supply-chain-program/, December 1, 2005

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started