Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Review the solution for Example 8.2 on page 175. For this example, we use two assignment rules: a. Prioritize tasks in order of the

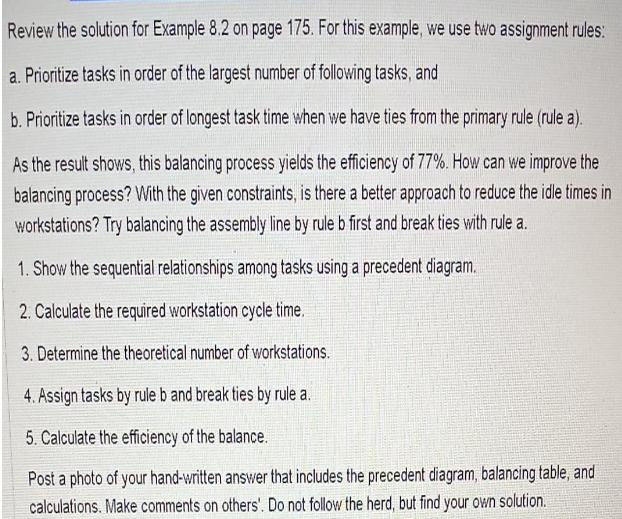

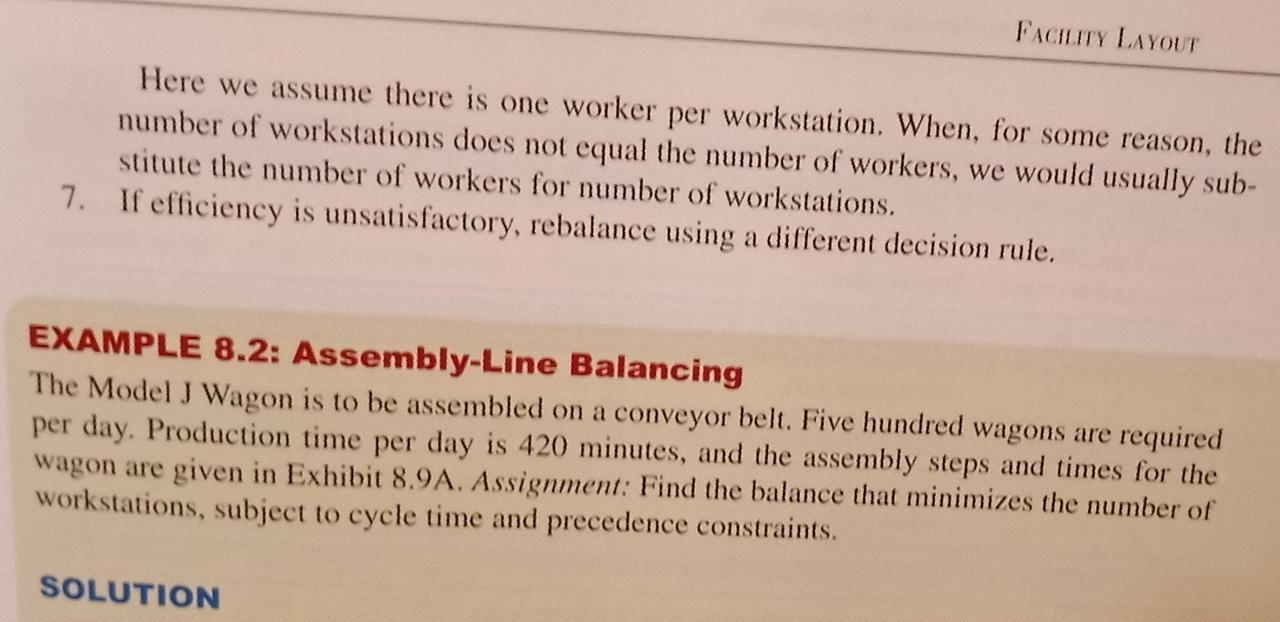

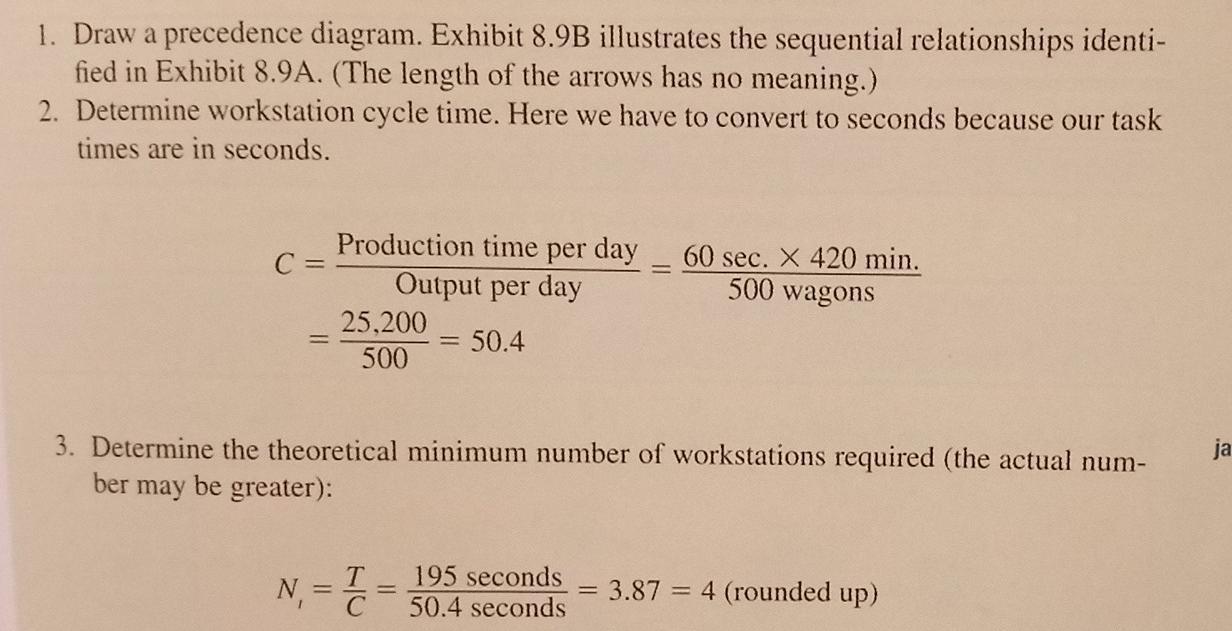

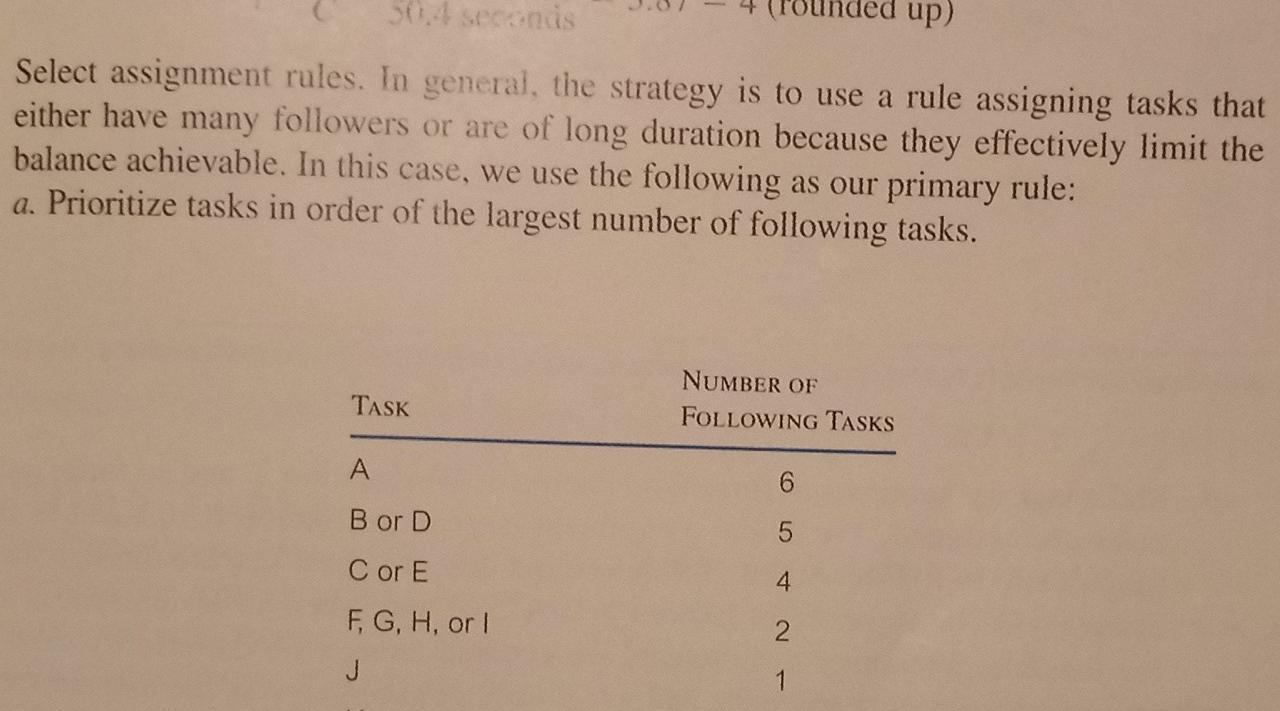

Review the solution for Example 8.2 on page 175. For this example, we use two assignment rules: a. Prioritize tasks in order of the largest number of following tasks, and b. Prioritize tasks in order of longest task time when we have ties from the primary rule (rule a). As the result shows, this balancing process yields the efficiency of 77%. How can we improve the balancing process? With the given constraints, is there a better approach to reduce the idle times in workstations? Try balancing the assembly line by rule b first and break ties with rule a. 1. Show the sequential relationships among tasks using a precedent diagram. 2. Calculate the required workstation cycle time. 3. Determine the theoretical number of workstations. 4. Assign tasks by rule b and break ties by rule a. 5. Calculate the efficiency of the balance. Post a photo of your hand-written answer that includes the precedent diagram, balancing table, and calculations. Make comments on others'. Do not follow the herd, but find your own solution. FACILITY LAYOUT Here we assume there is one worker per workstation. When, for some reason, the number of workstations does not equal the number of workers, we would usually sub- stitute the number of workers for number of workstations. 7. If efficiency is unsatisfactory, rebalance using a different decision rule. EXAMPLE 8.2: Assembly-Line Balancing The Model J Wagon is to be assembled on a conveyor belt. Five hundred wagons are required per day. Production time per day is 420 minutes, and the assembly steps and times for the wagon are given in Exhibit 8.9A. Assignment: Find the balance that minimizes the number of workstations, subject to cycle time and precedence constraints. SOLUTION 1. Draw a precedence diagram. Exhibit 8.9B illustrates the sequential relationships identi- fied in Exhibit 8.9A. (The length of the arrows has no meaning.) 2. Determine workstation cycle time. Here we have to convert to seconds because our task times are in seconds. C = Production time per day Output per day 25,200 500 = 50.4 T N = 1: C = 3. Determine the theoretical minimum number of workstations required (the actual num- ber may be greater): 195 seconds 50.4 seconds 60 sec. X 420 min. 500 wagons = 3.87 4 (rounded up) ja 50.4 seconds Select assignment rules. In general, the strategy is to use a rule assigning tasks that either have many followers or are of long duration because they effectively limit the balance achievable. In this case, we use the following as our primary rule: a. Prioritize tasks in order of the largest number of following tasks. TASK A B or D C or E F, G, H, or I NUMBER OF FOLLOWING TASKS 6 5 4 2 1 up) 1 0 Our secondary rule, to be invoked where ties exist from our primary rule, is b. Prioritize tasks in order of longest task time (shown in Exhibit 8.10). Note that D should be assigned before B. and E assigned before C due to this tiebreaking rule.

Step by Step Solution

★★★★★

3.49 Rating (162 Votes )

There are 3 Steps involved in it

Step: 1

ANSWER Cycle Time 60420500 504 sec Minimum number of workstations sum of total task times cycle time ...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started