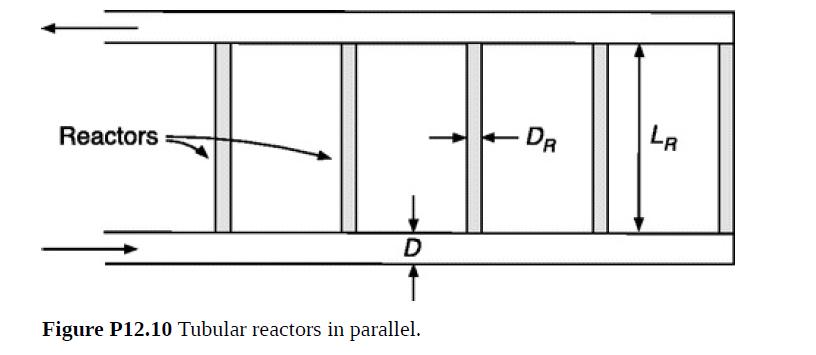

To boost production in a chemical plant without enlarging any of the tubular reactors, several might be

Question:

To boost production in a chemical plant without enlarging any of the tubular reactors, several might be arranged in parallel, as shown in Fig. P12.10. Each might be an open tube of diameter DR and length LR. Or, each might be a tube of those dimensions that is packed with spherical catalyst pellets of diameter d with void fraction ε. The mean velocity in an open tube and the superficial velocity in a packed tube are each denoted as vR. The reactants are supplied by a distribution manifold and the products collected via a return manifold. It is desired to derive pressure–velocity relationships that would help in designing such systems.

(a) Modify the derivation in Example 12.3-3 as needed to find P2 − P1 and vR for a tubular reactor without packing. You may assume that the flow is turbulent and that P0 is given. (Evaluating the inlet and outlet pressures at a given branch would require analysis of the entire flow network, manifolds and reactors.)

(b) Repeat part (a) for a packed-bed reactor in which![]()

(c) If vR for either type of reactor is given, find the pressure change at a branch point in the return manifold. Does the pressure there in the main pipe increase or decrease in the direction of flow?

Step by Step Answer:

Introduction To Chemical Engineering Fluid Mechanics

ISBN: 9781107123779

1st Edition

Authors: William M. Deen